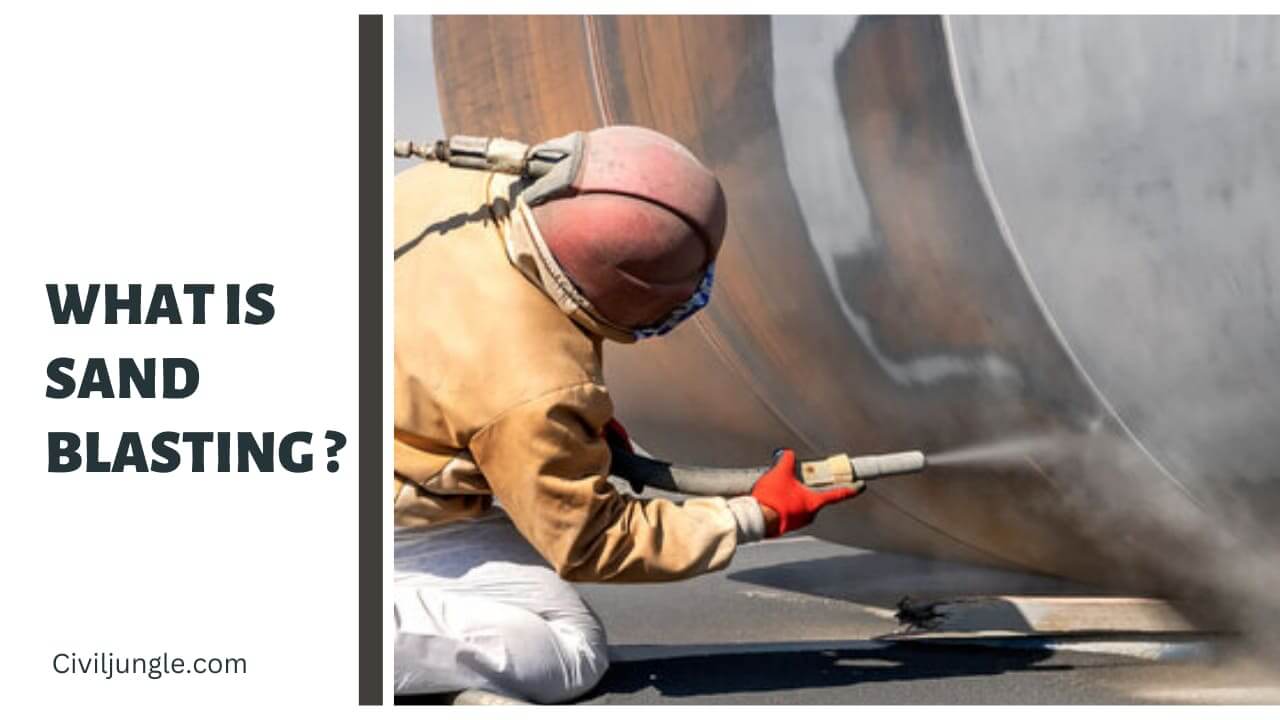

Sandblasting is a process where sand is blasted at steel or metal to remove rust, paint, or oil on the steel. Shot blasting is a similar service used to clean steel. However, shot blasting uses tiny steel balls to clean steel pipe and tubing. Shot blasting is popular because it creates a unique texture to the steel and promotes better paint adherence.

Sandblasting and shot blasting are quick, cost-effective, and prepare steel surfaces for further processing. After sandblasting or shot blasting, paint adheres better to the steel and fabrication becomes much, much simpler. Sandblasting provides new steel with a mildly abrasive cleaning, so you are left with a smooth surface free of imperfections.

There are Two Types of Sandblasting Processes

- Water-Driven- It is applied for reducing surface deterioration, most commonly water driven process is used for brick or concrete surfaces preparation

- Air-Driven - This process is best suited for metal surfaces, to prevent moisture buildup and avoid water intrusion in the surface. Sandblasting is the process of propelling abrasive by using the pressurized liquid or compressed gas as propellant. There are many generic terms for this process that is generally related to the sandblasting abrasive media used for this process. Here are the details of abrasive materials.